For any country, its manufacturing industry is the most important because it depends on it whether the country is self-independent or it has to import most of the things from other countries; you must have also read many times in tech machines and devices where it is written, Made in China, Made in Japan. So you must have also wondered how the manufacturing industry of these countries is so strong. Then, if you say that the manufacturing industry has grown because China has a large population, then you are totally wrong because India also has a large population, but it is not a manufacturing hub like China. The main reason behind this is automation software, which handles many repetitive tasks of manufacturing automatically, due to which the manufacturing cost comes down and labour cost also comes down, due to which they are able to export their products all over the world with a lot of profit.

But this is just the beginning, because in the next few years, advanced AI models will completely transform the manufacturing sector, so let us try to know in a little detail how AI can have a positive impact in sectors like manufacturing.

Quick Summary

The use of artificial intelligence in the manufacturing sector does not mean that its core focus is just on automation, rather AI models are going to transform manufacturing in a way where they will collaborate with machines using predictive maintenance to real-time analytics so that every stage of manufacturing is done with equal accuracy and speed, because manufacturing is not a fixed work but a combined process of different tasks in which each stage depends on each other.

In the future, due to AI, the efficiency of the manufacturing industry will increase, labor cost will be saved, product quality will also increase to a great extent and most industries will be able to do 24x7 manufacturing. With smart integration, AI will create opportunities for personalization, sustainability, and innovation like never before.

What is AI in Manufacturing?

The use of AI in manufacturing means that traditional machines that run in fairly repetitive processes can be automated to perform various production processes using intelligent algorithms and machine-based learning techniques. These technologies include machine learning, computer vision, natural language processing, and more. They're used to automate tasks, analyze datasets, make informed decisions, and even predict future outcomes. A lot of lives are also saved by automation because a lot of big tragic industry accidents have happened in the past. Bhopal gas leakage is also one of them. If automation had happened there, then such a big tragedy would not have happened.

This integration empowers factories to be smarter, faster, safer, and more responsive to dynamic market demands.

How is AI Being Used in Manufacturing?

If you are also curious to know how AI can be used in the manufacturing sector, then let's try to know in detail.

Predictive Maintenance: AI analyzes data from equipment to predict failures before they happen. This helps maintain the production unit, and the industry operates 24/7.

-

Quality Control: AI's computer vision systems catch defects in real-time, which never slows down the manufacturing process, because in traditional industries, the machine is fixed after it breaks down, which wastes a lot of time, but it shares information about machine health beforehand.

-

Demand Forecasting: Machine learning predicts market trends based on historical data. Before investing in any new industry, you have a detailed plan of that industry and future potential data, which greatly increases the accuracy of your decision.

-

Supply Chain Optimization: AI models streamline procurement and logistics. AI optimizes many operations in which it automates many repetitive tasks.

-

Smart Decision-Making: AI helps with real-time analytics and adaptive control in production. This helps the manufacturing department know when to take what decision so that manufacturing can be done as efficiently as possible.

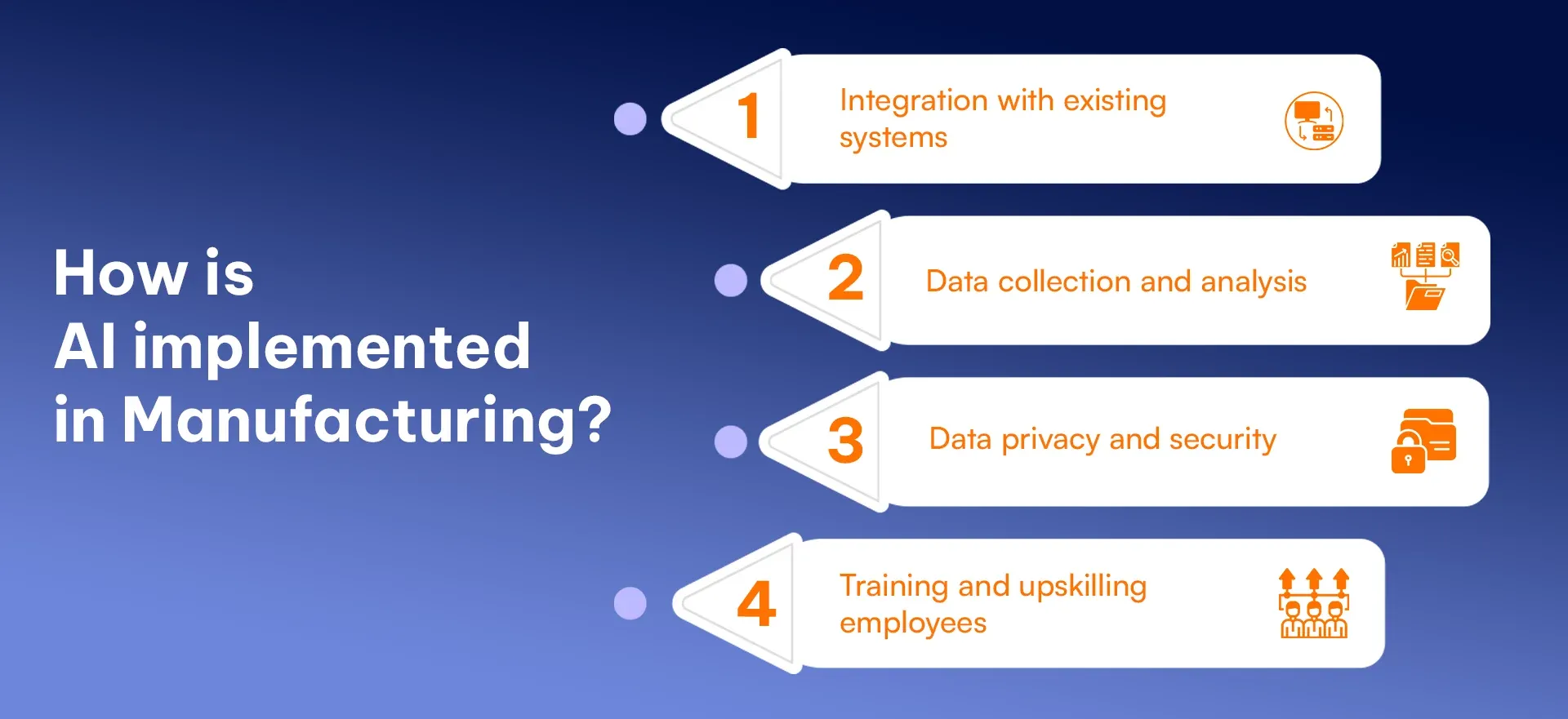

How is AI Implemented in Manufacturing?

Let us know how it is finally implemented in the manufacturing unit or system. Basically AI can be implemented in any manufacturing unit by following a very strategic and strong approach.

-

Integration with Existing Systems: AI must seamlessly mesh with legacy systems and software. This includes setting up APIs, middleware, and platforms that allow smooth communication between AI tools and ERP or MES systems and its Cross-functional collaboration feature between AI experts and IT professionals plays a very important role.

-

Data Collection and Analysis: Data is the backbone of any AI implementation. Manufacturers collect data from IoT devices, sensors, and production logs to train AI models. Ensuring the quality, consistency, and security of this data is crucial for meaningful insights.

-

Data Privacy and Security: With more data comes greater responsibility. Manufacturers must enforce strict cybersecurity protocols, ensure compliance with data protection laws, and set up access controls and auditing systems. Exact data management or handling is so important for industries to secure their business strategy.

-

Training and Upskilling Employees: AI adoption is not just about machines but people too. Workers need training on how to work with AI systems, interpret AI-generated insights, and adapt to new workflows.

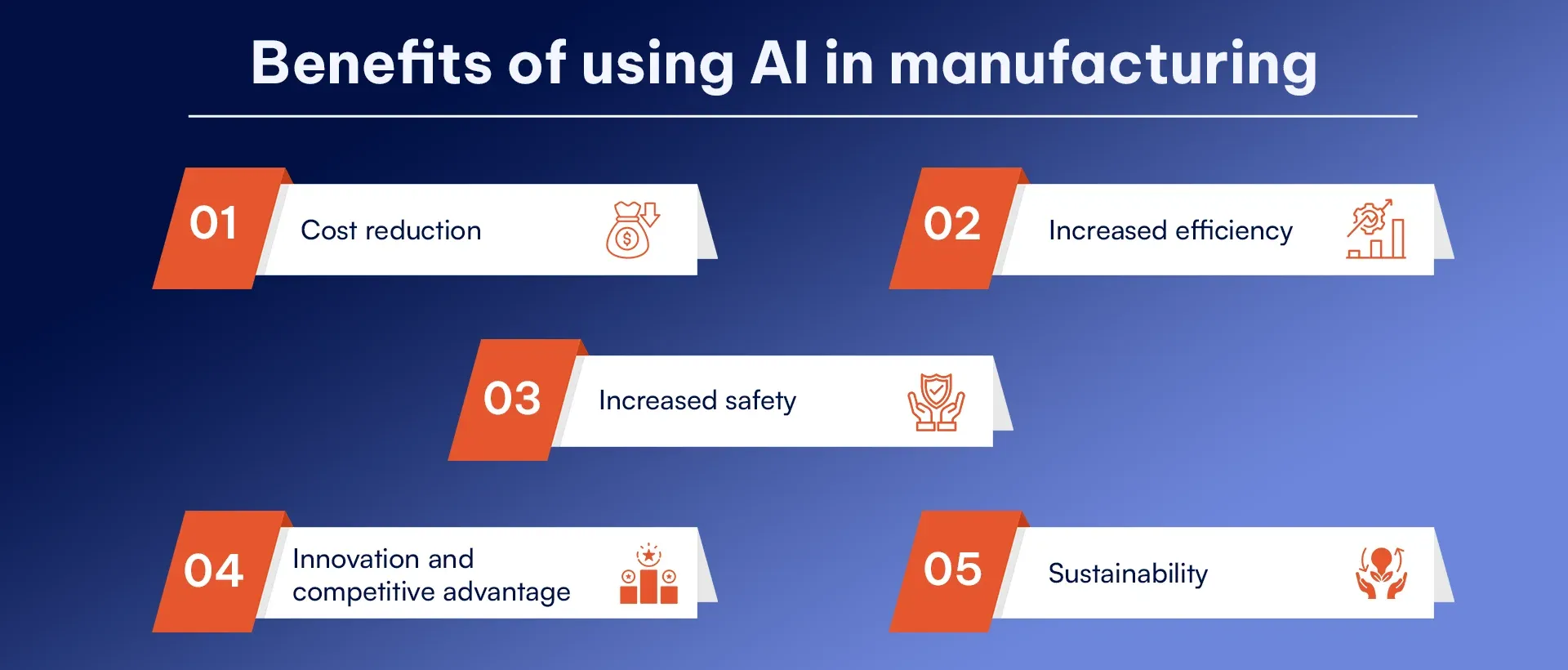

Benefits of Using AI in Manufacturing

We have already known about many benefits of using AI in manufacturing, let us know in some detail how exactly it benefits manufacturing.

-

Cost Reduction: AI minimizes unnecessary labor, prevents breakdowns, and cuts energy usage. Predictive maintenance alone can save thousands by avoiding unplanned downtime. Automation also reduces scrap and rework, improving material usage. With its integration the units can operate 24x7.

-

Increased Efficiency: AI accelerates repetitive tasks, frees up human workers for complex decision-making, and keeps production lines running with minimal intervention. Algorithms continuously monitor systems, enabling smoother workflows and faster output. Many experts say that AI integration has increased the production of machine units.

-

Increased Safety: AI-powered robots can handle dangerous or strenuous tasks. Smart sensors and computer vision prevent accidents by alerting workers or stopping machines when hazards are detected.

-

Innovation and Competitive Advantage: With AI, manufacturers can design smarter, prototype faster, and bring products to market more quickly. Digital twins simulate changes before implementation, reducing trial-and-error costs. This leads to rapid innovation and staying ahead of competitors.

-

Sustainability: AI enables sustainable practices by optimizing energy usage, reducing waste, and improving resource allocation. Smart systems can also track carbon footprints and help achieve green manufacturing goals.

Also Read: How AI is Transforming Real Estate: 2025 Tools & Trends

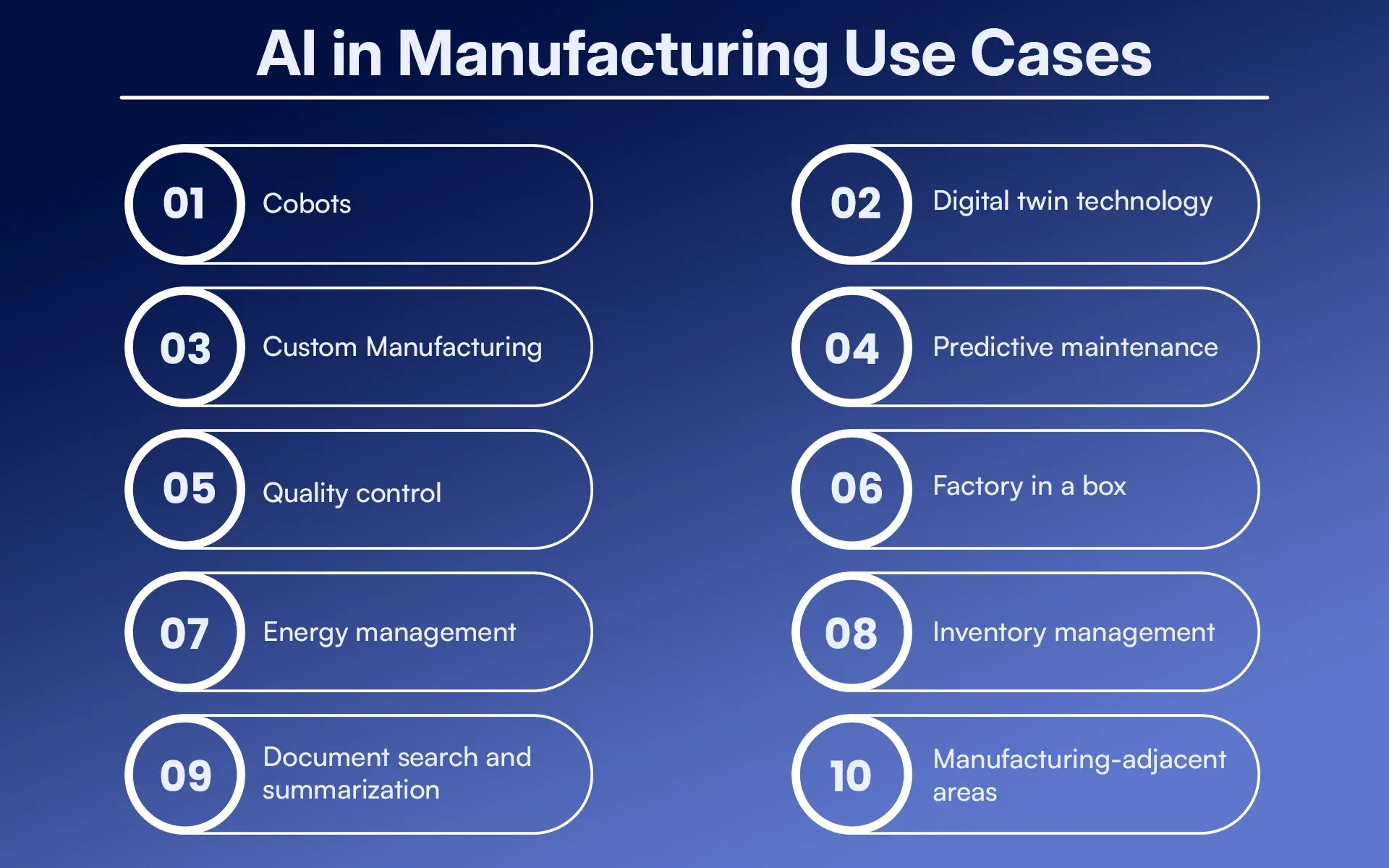

AI in Manufacturing Use Cases

Let us know in detail what the use cases of integration of AI in the manufacturing industry are.

-

Cobots: Collaborative robots work alongside humans, handling tedious or hazardous tasks while humans focus on complex problem-solving. Cobots increase safety, productivity, and adaptability. This has saved the lives of human laborers a lot.

-

Digital Twin Technology: A digital twin is a virtual replica of a physical object or system. In manufacturing, it mirrors real-time processes, enabling simulation, testing, and predictive analysis. This helps optimize performance and reduce downtime.

-

Custom Manufacturing: AI allows for mass customization without compromising speed or efficiency. Products can be tailored to individual customer preferences, and design iterations can be rapidly tested and deployed.

-

Predictive Maintenance: By analyzing equipment data, AI predicts when parts will fail and schedules maintenance accordingly. This reduces unplanned downtime, prolongs equipment life, and saves on emergency repairs.

-

Quality Control: AI-powered vision systems inspect products for defects with high precision. These systems work 24/7, ensuring consistent quality while reducing human error.

-

Factory in a Box: These are modular, mobile manufacturing units equipped with AI and IoT. They can be deployed anywhere to meet local demand, reduce logistics costs, and quickly respond to market changes.

-

Energy Management: AI optimizes energy consumption by monitoring usage in real-time and suggesting changes. It helps manufacturers reduce their carbon footprint and cut utility costs.

-

Inventory Management: Machine learning algorithms forecast demand and automate inventory replenishment. This ensures optimal stock levels, reduces holding costs, and avoids production delays.

-

Document Search and Summarization: Generative AI tools can process large volumes of technical documents, extract relevant information, and summarize it. This helps engineers and managers find what they need faster.

-

Manufacturing-Adjacent Areas: AI is transforming other areas too, like customer service, product support, call processing, and partner engagement. Chatbots handle inquiries, while analytics improve customer satisfaction and supply chain relationships.

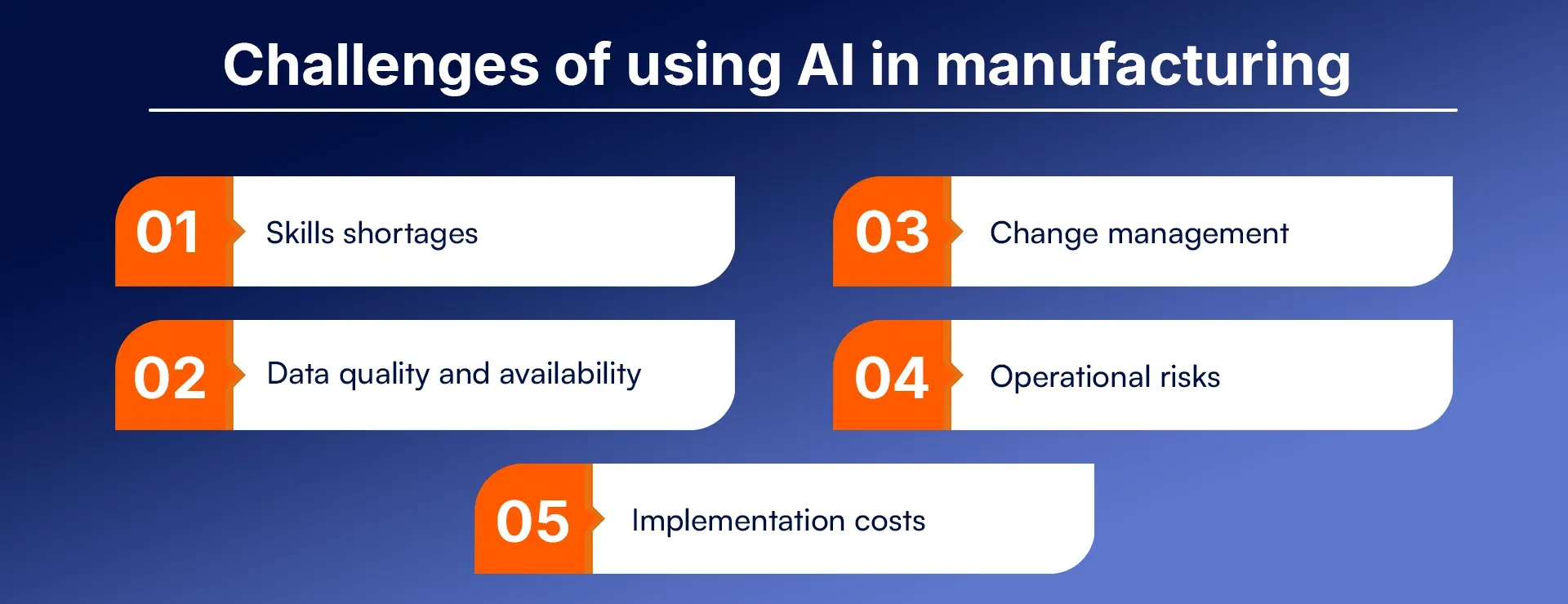

Challenges of Using AI in Manufacturing

There are many benefits of using AI in the manufacturing industry but it is also challenging because manufacturing is a very traditional industry, and AI integration in it is also quite problematic, so let's discuss it in detail.

-

Skills Shortages: There is a lack of professionals skilled in AI, data science, and machine learning. Companies need to invest in training or partner with external experts to build internal capabilities.

-

Data Quality and Availability: AI systems are only as good as the data they receive. Incomplete or poor-quality data can skew results, especially in applications like quality control and predictive maintenance.

-

Change Management: Employees may fear job loss or feel overwhelmed by new technologies. Clear communication, involving them in the transition process, and showing the benefits can ease this resistance.

-

Operational Risks: AI models may not always be perfect. Errors in predictions or decision-making could halt production or cause defects. Regular monitoring and contingency planning are essential. Rather they use Ai automation but the company required human employees for work monitors to avoid any issues and quality check.

-

Implementation Costs: To setup Ai companies requires high upfront investments in infrastructure, software, and training can be a barrier, especially for small and medium-sized enterprises. However, long-term ROI often justifies the cost.

Conclusion

Even if the manufacturing industry is operating on traditional machines, after 2020, many industries are shifting to AI automation. This is not only for cost saving or increasing production, but AI automation also increases safety a lot because there were many earlier jobs that were very dangerous, which AI has easily replaced.

However, it can be difficult for small businesses to integrate AI into their manufacturing because they use a lot of traditional machines and do not have that many skilled employees, and they have to pay a lot of upfront setup costs for AI integration, but it is worth it in the long term. Overall, if the industry needs to grow and the competition needs to be beaten, then they will have to shift to this.

RejoiceHub can help. With our AI development services, we assist manufacturing businesses big or small in seamlessly integrating AI solutions tailored to their needs. From upgrading traditional systems to deploying smart automation, RejoiceHub is your trusted partner in future-proofing your operations.

Frequently Asked Questions

How is AI used in the manufacturing industry?

AI is used in predictive maintenance, quality control, demand forecasting, real-time monitoring, energy optimization, and more. It helps automate processes, enhance safety, and reduce costs.

What is generative AI in manufacturing?

Generative AI designs new products, optimizes components, and automates document creation. It can generate blueprints, test ideas, and support creative innovation in product development.

What are the concerns about AI in manufacturing?

Concerns include job displacement, high implementation costs, data security, and model accuracy. Ethical and transparent use is essential.

Is AI only suitable for large manufacturing companies?

Not at all, while large companies may adopt faster, SMEs can also try to use AI tools, especially cloud-based and scalable solutions that fit their budgets. In the short term it's so expensive for them but in the long term it's so profitable.

How can manufacturers get started with AI?

Start by identifying areas with clear ROI potential, like predictive maintenance. Partner with experts, invest in training, ensure high-quality data, and Initially, do integration in a small unit and expand its use on the basis of testing.